Custom Hot Stamp Program

Are you running a tournament or do you need custom discs for your local disc golf club or company? See below for order details, art specifications, and minimum order requirements.

If your order is for a PDGA-sanctioned event, click here for a sponsorship opportunity. Send your art and completed custom hot stamp order form to custom@dynamicdiscs.com.

3 week lead time for US orders, 5 week lead time for international orders.

Shipping and sales tax are NOT included in the total on the custom hot stamp order form.

If you are using Numbers on a Mac, please export to an Excel file before submitting your order form.

Order Requirements

50

Piece minimum

(discs or minis, not a combination of both)

10

Disc minimum per mold

$75

Setup fee on all orders – full size discs and mini discs require separate setup fees

$20

Setup fee on all re-orders

Custom Hot Stamp Templates

Each file includes full disc, junior, and mini templates.information about your store with your customers.

Describe products, share announcements, or welcome customers to your store.

Photoshop Template (.psd)

PDF Template (.pdf)

Custom Hot Stamp Assets

We have included baskets, discs, chains, grass, trees, and company logos to help you create your custom hot stamp.

Illustrator Template (.eps)

PDF Template (.pdf)

Please submit your custom hot stamp design to custom@dynamicdiscs.com.

All submissions and requests are subject to art fees starting at $40/hour.

Artwork Requirements

All submitted images will be accepted at the discretion of Dynamic Discs. Any stamp found to be copyrighted, vulgar, violent, or offensive will not be tolerated.

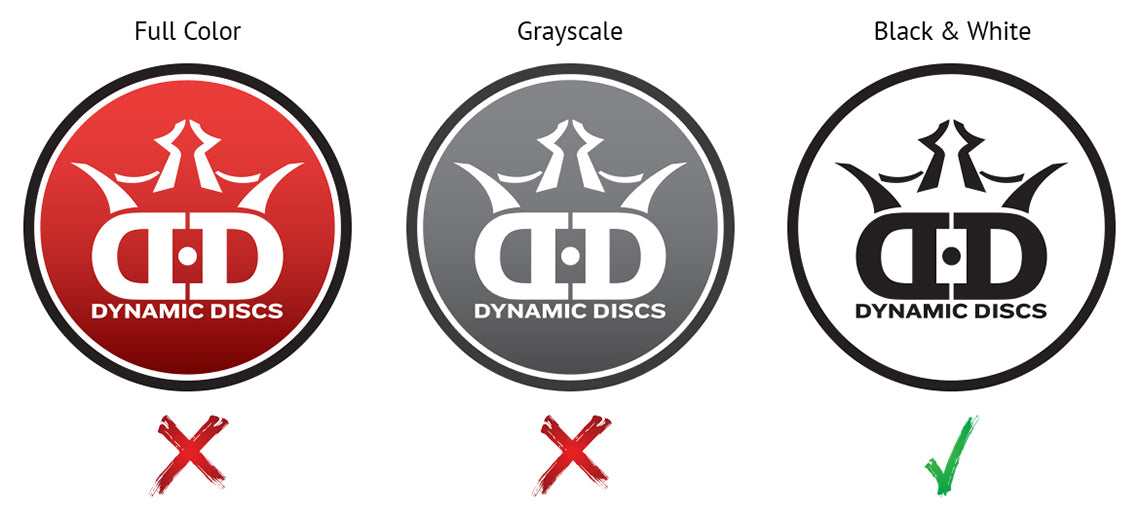

Hot stamps should be submitted as 100% black and white.

300 ppi @ print size or higher is necessary to achieve a good stamp.

Acceptable file types are .ai | .eps | .jpg | .pdf | .png | .psd | .tif

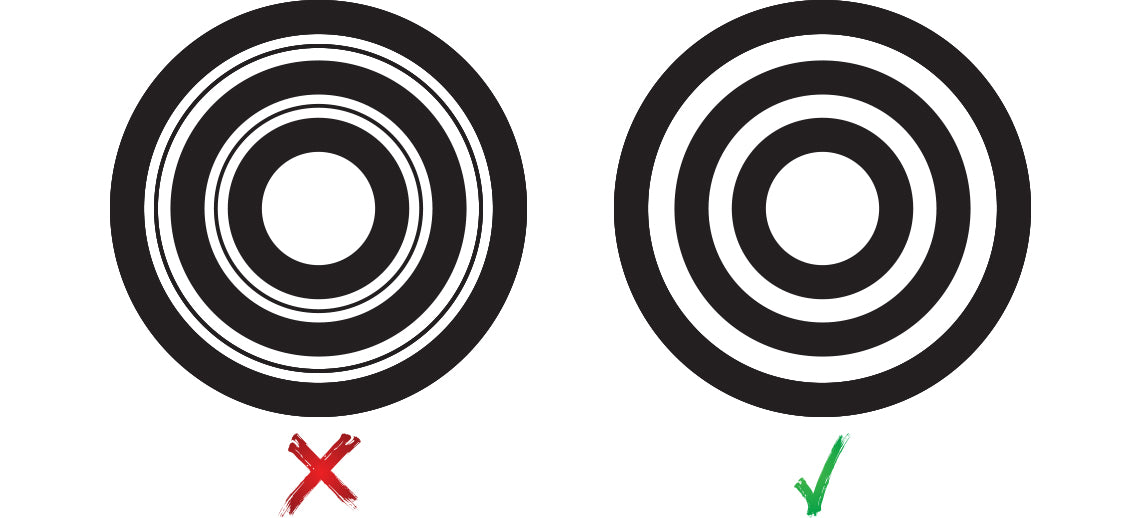

Thickness and Coverage

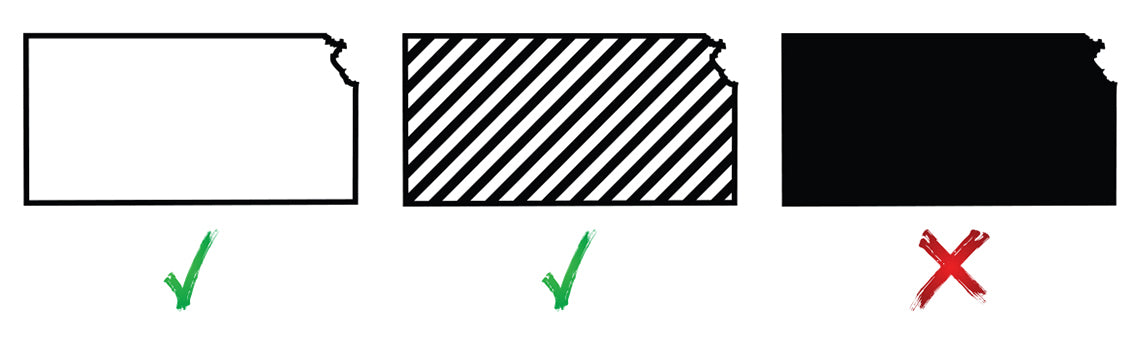

Avoid solid coverage areas.

Large solid areas do not stamp well.

Outlining usually solves the problem, as shown above in the first and second image.

Avoid covering the center of the disc when possible.

Covering the center of the disc nearly guarantees a drop-out/misprint.

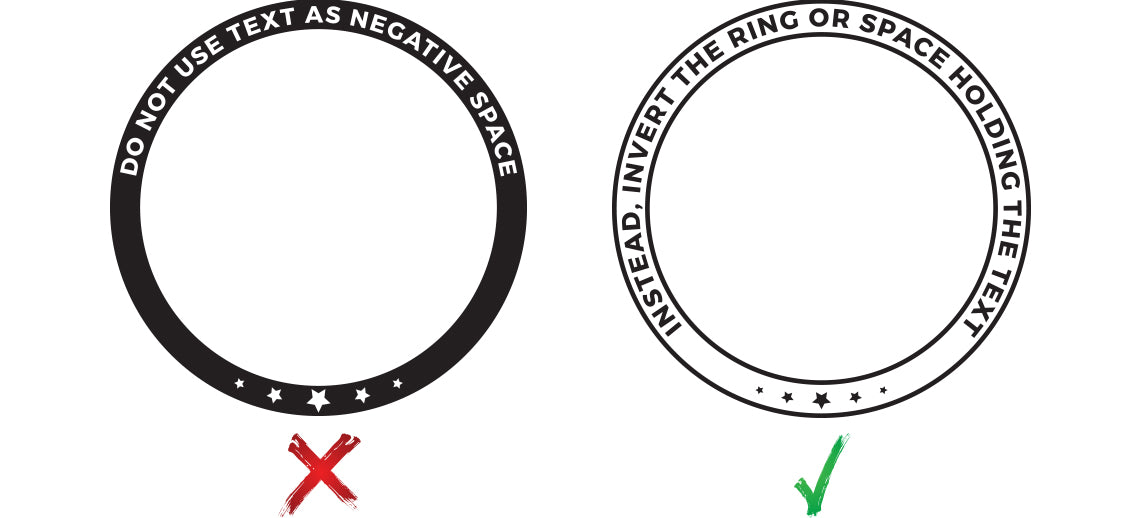

Do not use text to break up thick spaces.

Instead, invert the area and have the text be the area that gets stamped.

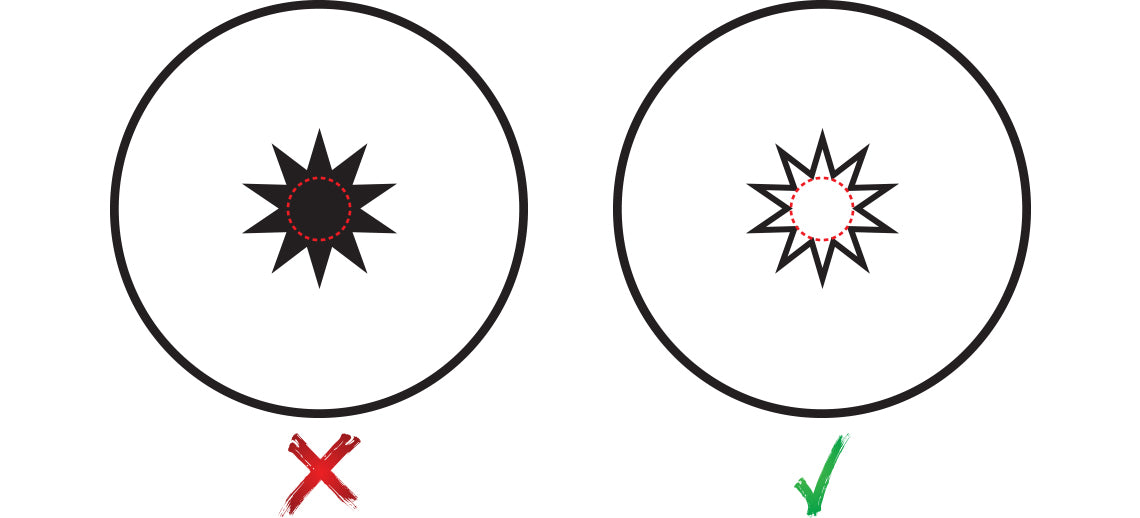

Avoid thick and thin lines that are close to one another.

This will cause the stamp to bleed together.

Keep consistent thickness in concentrated areas.